Consulting & Coaching on Organization Development & Building High-Performance Teams with a Manufacturing Company. An ‘Impact Project Team’ was formed, representing vertical and horizontal sections of the company.

We met and decided to investigate, using a systems-analysis approach, a significant machine that broke down after a scheduled shutdown. The company could not get running again, costing the company millions per month in lost revenue.

Situation

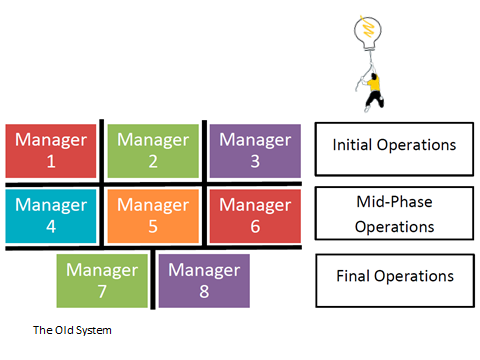

This complicated and expensive machine required specialized skilled-knowledge. The machine ran continuously with eight managers and operators. Each manager and operator were responsible for only their area of the machine and its operation.

Each machine manager and operator was trained, experienced, high-performing employees and was proud to have ownership and responsibility for their piece of the machine.

When we interviewed them, each stated in one form or another, “This area of the machine and ensuring quality completion from x to y in the SOP is my area of focus. My area has not had a breakdown in months.”

They were right.

During scheduled machine maintenance, different managers decided to work with their operators on improvements. However, these improvements were only focused on their area of responsibility.

When the scheduled maintenance was over, they turned the machine on, and it did not work.

- Increased defective and wrong products produced

- No single person knew all the changes made during the machine maintenance

- No single person knew how or if they could reverse the “improvements” made to the various machine areas

- What they knew was that the machine was not working as it was supposed to, and they were losing money

Intervention

The Impact Project Team and I knew the people were competent, hard-working, and doing the best they could. This breakdown was not a “people problem”… it was a system problem and would require a change in the system of work to change the people’s behavior.

The intervention was to find a way to integrate the manager and machine operators into a Machine Team with shared Goals, Roles, Priorities, and acceptable Behaviors.

Resolution

- The VP of Operations was made accountable for the output and cross-functional teamwork of the people on the Machine Team.

- A clearly defined and shared Goal and Purpose of the teamwork statement was created.

- The Machine Team Collectively managed the whole process. No one machine manager and operator “owned” or was responsible for any one part.

- Any improvement and change were to be proposed and approved by the Machine Team.

- Improvements required research and investigation before being proposed. The formal review process followed and adaptation of ‘7 Steps to High-Performance Teams‘ + a logic model for proposed improvements.

This became more than just creating and sustaining a team. We worked through a culture change.

It required a change in how the organization recognized and rewarded teamwork—a change in how the managers and machine operators thought of their work. A change in how work got done and who could do + approve the work happened while maintaining and respecting the autonomy and skills of the people—a change in how people related to each other.

Using real work for Team Building moved the people on the team

- from functional autonomy to interdependence

- from lone experts to a collaborative, focused team

- from impulsive to disciplined

- from the use of experience and instinct to the use of data

- from separate functions to systems thinking

Changing the system and how the work is done can change people’s behavior. I believe everyone wants to do their best work, and systems drive behavior. Improve the systems, and unleash the capacity of people to do great work and love what they do.